New tool brings Discrete Element Modelling to the fore

EDEM, the market leader in Discrete Element Method (DEM) technology, is changing the face of Computer Aided Engineering (CAE) with a revolutionary new software that will make bulk material simulation accessible to all engineers using Finite Element Analysis (FEA) and Multi-body Dynamics (MBD) software, in the design of heavy equipment.

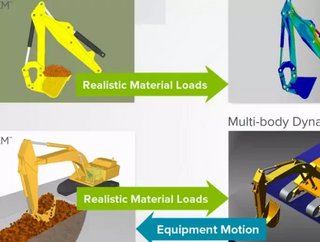

The new products called ‘EDEM for’, integrate with leading CAE software tools from ANSYS, MSC Software and Siemens and do not require any DEM expertise to use. ‘EDEM for’ will provide design engineers with an easy to use, bulk material simulation system which links with their MBD and FEA software, extending the capability of the host software and providing engineers with unique insights into how materials interact with their equipment.

Traditionally, bulk material simulation has been the realm of a small pool of DEM experts due to its complexity – this has acted as a major barrier to uptake for many design engineers with only a small number of Original Equipment Manufacturers (OEMs) currently using DEM capability. ‘EDEM for’ will make DEM accessible to a wider number of engineers, who can now benefit from new insights into material-machine interactions, without the need to learn a new technology.

Through ‘EDEM for’, design engineers working in the construction, off-highway, mining and heavy industry sectors, will no longer have to rely on hand calculations and assumptions to predict the effect of materials on their equipment. ‘EDEM for’ provides engineers with a unique library of thousands of material models, representing a wide range of real materials such as rocks, soils and ores. The database delivers accurate and realistic information on the forces and material loads acting on equipment. All the analysis is then carried out by the host software, in an environment familiar to the engineer. Having easy access to a bulk material simulation capability will help improve design accuracy, reduce expensive physical prototyping and ensure confidence that the design requirements will be met.

The launch of ‘EDEM for’ comes at a time when the CAE industry is rapidly moving towards software integration and multi-physics platforms, providing maximum functionality and capability for the user. The next challenge is to ensure complex simulation tools that sit within their host program are accessible and easy to use. ‘EDEM for’ is the first DEM tool to be offered as an add-on to FEA/MBD software to achieve this.

Richard LaRoche, Chief Executive Officer of EDEM, comments:

“We have been working closely with our technology partners and our customers to develop co-simulation solutions between EDEM and their FEA and MBD tools. The drive to multi-physics platforms is a trend that is only going to continue, but the challenge remains ensuring that the software which integrates with the host platform is actually usable for engineers without the need for extensive training. With ‘EDEM for’ we are taking co-simulation to the next level by enabling engineers with no DEM knowledge to benefit from the key insights that this technology brings. Our ultimate goal is to fully democratize DEM so it is available to all engineers, not just the experts.”

EDEM’s market leading DEM software is widely used in North America, Europe and Asia across a range of applications within the mining, construction, heavy industry and agriculture sectors, from specialist mining machinery, excavators, back hoes and truck bodies to skid steer loaders, bull dozers, underground mining shuttle cars, drag line buckets, ploughing and seeding equipment and many other mechanical applications that work with bulk materials.

The first ‘EDEM for’ to be released in the next month, includes EDEM for ANSYS, EDEM for Adams and EDEM for LMS Virtual.Lab Motion, with plans to include solutions for other MBD and FEA software packages in the future.